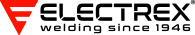

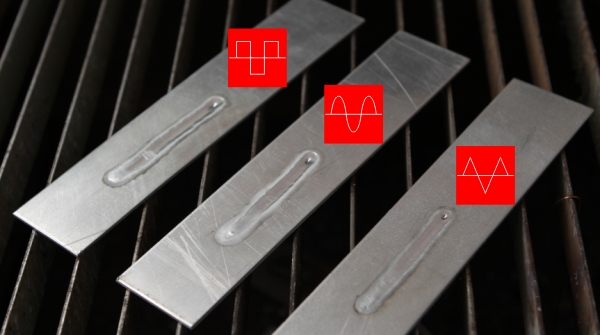

Wave forms AC welding

The old TIG machines with conventional technology used the sinusoidal waveform in TIG welding in alternating current (AC). Nowadays, the new inverter TIG AC/DC machines allow the selection of various waveforms in TIG welding in alternating current (AC). This selection, without changing other parameters of welding, allows to change the characteristics of the arc, the seam, and the cleaning / penetration effect.

Square wave:

Welding of light alloys with more penetration into thick plates. It forms a more “strong” arc, then more rough and noisy, where there is more heat transfer. It forms a broader and thicker seam.

Sine wave:

Is used in most applications.

The arc is smoother and less noisy than the square wave.

Triangular wave:

Welding of thin plates with little transference energy and thus, less penetration. It reduces the distortion of the parts and allows a fast solidification of the welding bath. It is especially recommended for thin-thickness aluminum.