Welding inverter MIG 604 MW BASIC

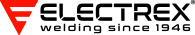

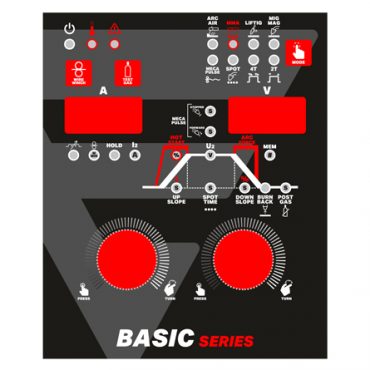

Three-phase inverter for MIG/MAG welding with separated wire feeder, coated electrode MMA and LIFTIG welding in direct current. Modular equipment for easy displacement and cooling unit option. Two displays for simultaneous reading of welding current and voltage and HOLD function. Electronic inductance adjustment for filling or penetration welds. Excellent arc ignition for jobs with wire […]

- Three-phase inverter for MIG/MAG welding with separated wire feeder, coated electrode MMA and LIFTIG welding in direct current.

- Modular equipment for easy displacement and cooling unit option.

- Two displays for simultaneous reading of welding current and voltage and HOLD function.

- Electronic inductance adjustment for filling or penetration welds.

- Excellent arc ignition for jobs with wire from Ø 0,8 to 1,6mm (solide) and Ø 0,9 to 2,4 (fluxed).

| Input voltage | 3x400V (+/- 10%) |

| Frequency | 50/60 Hz |

| Maximum primary current (MIG/MMA/TIG) | 60,2/60,2/48,9A |

| Maximum power (MIG/MMA/TIG) | 41,3/41,3/33,4KVA |

| No-load voltage | 93V |

| Current regulation | 40-600A |

| Duty Cycle 40% | 600A |

| Duty Cycle 60% | 530A |

| Duty Cycle 100% | 430A |

| Wire diameter (Solid/fluxed) Ømm | 0,8-1,6/0,9-2,4 |

| No. Feed Rolls - Motor Power | 4R - 75W |

| Wire speed | 0,5-30 m/min |

| Spot welding time | 0-10 s |

| Post-gas time | 0-10 s |

| Protection | IP 23S |

| Insulation class | H |

| Weight | 107,5kg |

| Dimensions (HxWxL) | 1140x470x1030 |

Features

Multi-Process

Multi-Process machines, MIG/MAG, TIG and MMA welding, all on the same equipment.

MecaPulse

Low heat continuous welding with less workpiece distortion and excellent gap bridging of thin plates. Great reduce of wire and energy consumption.

Inductance

Electronic inductance adjustment for filling or penetration welds.

Digimig torch

Adjustment of wire speed, voltage and work memory selection directly on the torch, without the need for the operator to move to the welding equipment.

Cutting e Gouging

ARC-AIR function for cutting and gouging.

Applications

- Heavy and medium metal workshops

- Metallic structures

- Solar and wind industry

- Shipbuilding and offshore

- Automobile industry

- Aerospace, railway, mining and oil industry

- Pipelines

- Services, repair and maintenance