Basic Questions Before Buying a Welding Machine

What material to be welded?

In addition to your experience or the learning curve for each welding process, the metal to be welded will greatly affect the welding machine you will buy, as each machine will only have specific welding processes available*.

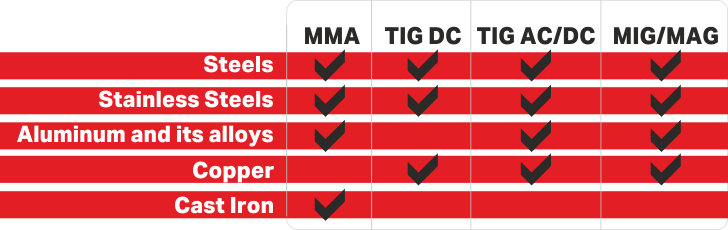

Here is a table of the metals to be welded and the respective welding processes you can use:

Within the TIG, we distinguish the DC TIG and AC/DC TIG variants, because it is only possible to weld aluminum and other light alloys with the AC TIG variant (TIG in alternating current).

*Note: there are machines with more than one welding process available. These are the multi-process.

Machine power supply?

To buy a welding machine, you need to know what type of supply voltage is available at the place where you are going to weld. If you go to DIY jobs at home, you will probably only have single-phase electricity. If it is in a company, you will also have the option of three-phase voltage (usually 380 or 400V). Be careful when buying from foreign sites, as there are machines prepared for other voltages that are not available in your country.

What is the place where you are going to weld?

It may seem like a secondary aspect, but the place where you are going to weld is very important when choosing your welding machine. For example, if you go outdoors, in a location with wind, the best options are stick welding machines (coated electrode). In this welding process, unlike MIG and TIG, the electrode already has gas protection in its coating so that the wind will not compromise the quality of your welds.

Where you are going to weld can also influence the type of design of the welding machine. To weld in a place where there are obstacles (for example, a shipbuilding workshop or a civil construction work), your machine must have portability and mobility, allowing the welder to transport it from place to place. In this case, in addition to compact and light machines, MIG/MAG machines with a separate feeder are good options.

Long or short weld beads? Thick or thin materials?

The length of your welds and the thickness of the workpieces to be welded will influence the current range and duty cycle that your machine will need to have. The current range will depend on the thickness of the metal to be welded, so the thicker it is, the more power the welding machine will have to have. The machine’s duty cycle will comprise how long you will be welding at a given amperage or welding current. For example: if the machine specifications states that the welding current is 200A – 60% and 160A – 100%, it means that the welding machine will weld for 6 minutes with a welding current of 200 Amperes and with a current 160 amps can run continuously. After this time of 6 minutes, the machine will probably turn on the thermal protection so you will have to let it cool down. The current range and its duty cycles must be considered and are a good comparison between different brands of welding machines.

Machine’s price?

The budget you have available for your new welding machine is a subjective matter and no longer depends on the factors described above. Remember that after-sales service, machine durability and welding results must also be considered and that they often require higher investments, which pay off in the long term.